|

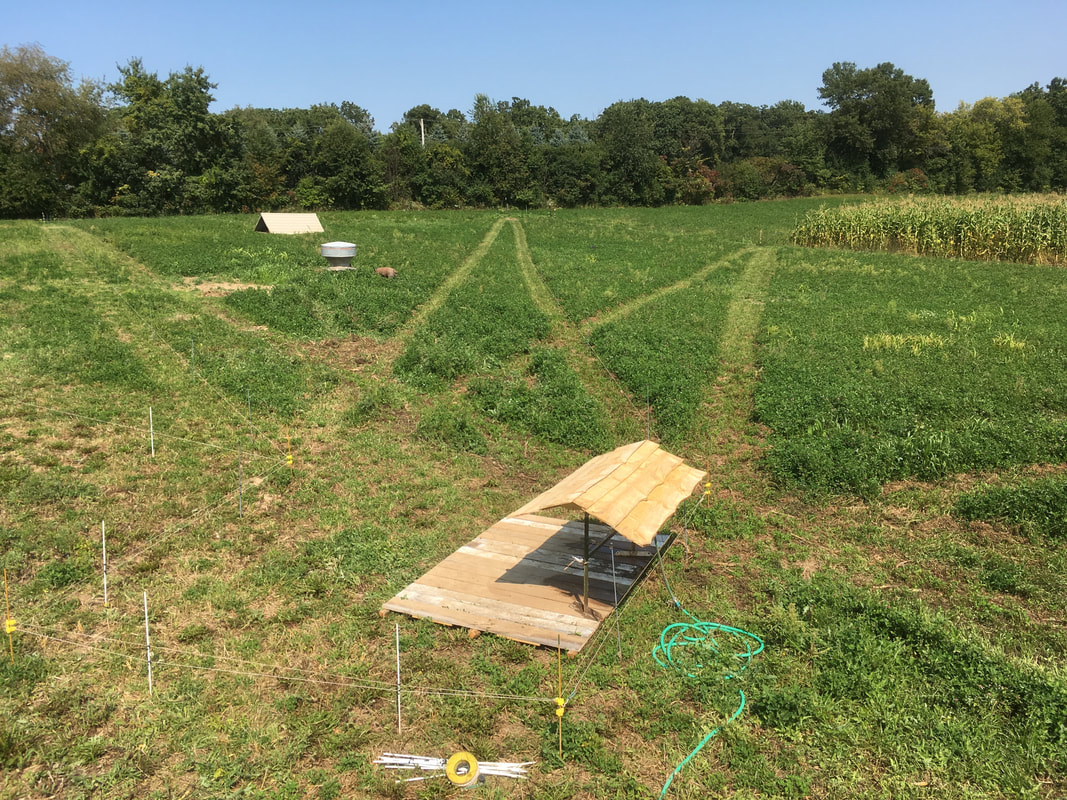

Call it a wagon wheel, spoke-and-wheel, or a pie. It’s a system of grazing a pasture by moving the animals around a fixed center point. After trying this system with cattle a few years ago, I adapted it to pigs. I call it the pig-star.

Without a tractor on the farm, I needed a pasturing system that let me move pigs easily. Otherwise, if I left them in place too long, they would tear up a pasture beyond easy repair. When you only have pitchforks, shovels, and a tiller, pasture renovation isn’t easy. Pigs need water, shelter, and feed. The hardest thing for me to move is the watering system, so I built the pig-star with my watering system—what I call the water-deck—in the center. I fenced in eight acres of pasture this year with two-strand steel electric fence. I don’t need that much fenced in but it’s easier to build big and not need it than to have to fence in more pasture in mid season (Experience, thou art a tough teacher). I lay out one to three-acre paddocks depending on the pasture constraints and the size of the pigs —larger animals need more space. A mapping app on my phone helps me find the center of the paddock and get the most even divisions. Then I make a fifteen by fifteen foot box in the middle of the paddock for the water deck and set steel electric fence posts at the box corners. I mow lines from every dividing point on the outside perimeter to two of the posts around the water deck; some of the divisions require me to change the fence opening to the water deck and some do not. The resulting layout looks like star (see photo above). I divide the paddocks with single strand of poly wire (synthetic twine with stainless wire in the strands —lightweight but still carries a shock) and fiberglass posts. I use separate wires for each leg of the star and and always have the next leg set up as well. When I need to move pigs, I unplug the fence, unroll the wire between the old and new divisions, move the feeder and shelter, and put the wire back up. Then I take the outside wire of the previous division and set it up for the next new division. I can move pigs in less than ten minutes this way. It takes a couple minutes longer if I change which side of square is open to the water deck or rotate the water deck itself. I’ve been told several times that once pigs are trained to electric wire, they won’t cross where a wire has been. A lot of farmers recommend putting up hog panels where you change paddocks so the pigs will cross easily when you take down the pannel. I used to do that and decided it was too much labor. Though they were hesitant the first few times I moved them, my pigs quickly learned to cross into new pasture as soon as I rolled up the dividing wire. I also feed them ear corn (and now acorns) from a bucket every day. They run to the sound of me banging on a plastic bucket. I fill the feeder every other day and time it so that it’s empty when I need to move them. Then I tilt the feeder on its side and roll it to the new division. I put old cultivator gauge wheels on one end of their shelter so I can pick up one end and move it more easily. Both have tow hooks on skids underneath so I can drag them with my BCS for longer moves. I’ve had people tell me that I need a four wheeler or UTV for all of this. I’ve watched farmers get off and on a machine to open and close gates, off and on to cross wires, off and on to fill the feeder, etc. At this scale, I can carry two bags of feed straight from barn to feeder and step over fences faster than I could do it with any machine. If you go through a ton of feed per week though, that’s a different situation. That’s the pig star. They are in their third “star” for the summer. I only use the BCS when I move them to a new star, about once a month. So I can go a month at a time without firing up an engine to move or feed pigs. When you look at the labor/overhead/environmental factors equation, it’s not a bad way to rotate pigs through pasture.

0 Comments

A customer who dropped by the farm for the “nickel tour” saw my tool tote and thought it was wonderful that I was using “that old toolbox”. I used to think that carpenter’s totes like the one above were quaint relics best used as planters and country decor. Then, a couple years ago, I made one as one-hour hand tool project using barn wood from our farm in Watertown.

I can get 50 lbs of tools in a Bucket Boss, but it’s not handy to carry. The classic tote, with a tool racks along the inside, lets me carry plenty of tools more comfortably than a bucket. The narrow cross-section puts the weight closer to my body, making it feel lighter. Though lidded tool boxes with drawers keep dirt out, and they’re great for mechanic’s tools, they’re much slower to access. For taking a few tools to the task, the tote rocks. Everything stands up in a tote so it’s easy to grab a tool, use it, and put it back in it’s slot. I use this tote for chainsaw gear when I’m milling logs, for carrying axe, maul, and wedges when I’m splitting wood, and for fencing tools. It’s easy to slip stuff in and out of it as seasonal tasks change. Sometimes the only way to understand why people did things a certain way is to try it. Who knew that an 19th Century styled carpenter’s tote could still be so handy? |

Ryan Erisman

Former Marine Infantry Officer. Iraq Vet. Interested in Regenerative Agriculture at any scale. Archives

February 2023

Categories |

Odyssey Farm, LLC.

The Odyssey Farm Journal

Odyssey Farm, LLC

|

Dane County Climate Champion

|

608.616.9786

|

Copyright © 2016

RSS Feed

RSS Feed